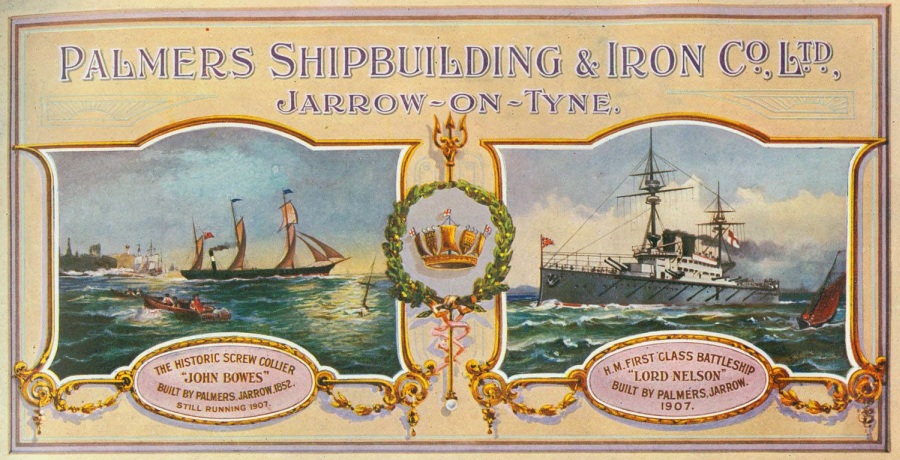

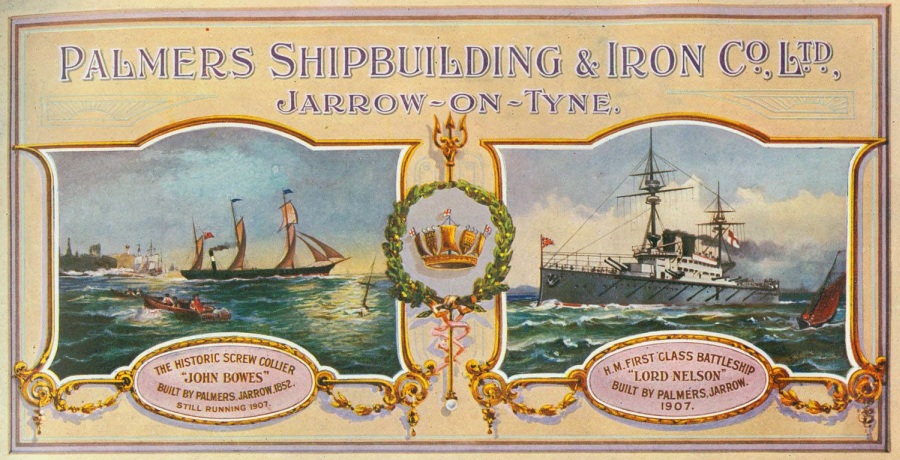

Palmers' Shipbuilding & Iron Company Ltd - History

More: |

Above advert is copyright of Tyne & Wear Museums

|

Palmer Brothers & Co (1851 - 1865) Palmers' Shipbuilding & Iron Co Ltd (1865 - 1933) Charles Mark Palmer was born in 1822, the son of a prosperous South Shields businessman and ship-owner. He initially worked for his father and then joined John Bowes in his colliery, where he rose to be a manager in charge. In 1851 he established his own shipyard at Jarrow with his elder brother George. The company, Palmer Brothers and Co, was established to build steam colliers to ship coal to London. The land for the yard had previously been used by Thomas Metcalf(e) for the building of wooden sailing ships and was leased from Mr Carr-Ellison of Hebburn. Charles' interest in steam colliers lay in reducing the cost of transporting coal from his County Durham mines to his major market in London. Steam power instead of sail meant more voyages per ship per year. Iron hulls instead of wood meant larger stronger ships could be built carrying more coal per voyage. The drive to reduce transport costs was forced on Charles by his major competitor in the London market, the coalfields of South Yorkshire and the Midlands which were much closer to London and were investing in canals and railways. The cost per ton per mile became a critical factor. In 1852 Palmer Brothers and Co launched their first ship, a paddle tug called NORTHUMBERLAND. Their second ship launched in 1852 was the world's first commercially successful sea going screw collier, the JOHN BOWES. The company went on to build a further 24 colliers of some 12,210 grt in the two years following the launch of the JOHN BOWES. Another innovation was the use of water as ballast as opposed to chalk rubble. A certain amount of ballast was required for the return voyage from London to provide weight and therefore stability for the ship. Loading and unloading the chalk was expensive, especially as the chalk was usually discarded at the end of the voyage. Water ballast provided a much more cost effective solution and Palmers' first yard manager was John McIntyre who had invented an improved type of water ballast tank. In 1853 Palmers had started an engineering side to the business to build engines & boilers for their vessels. The machinery for a vessel could often be worth about 50% of the value of a shipbuilding contract. The first ship with Palmers' engines was the JARROW of 1853. Charles purchased 14 collieries to safeguard his coal supply and leased land in North Yorkshire to mine iron ore through his Grindle Park Mining Company. He also built a harbour at Port Mulgrave near Staithes to ship the iron ore back to Jarrow. Charles also had interests in the Tyne Plate Glass Company to supply ship’s fittings and the Bede Metal Company to supply copper. Additional berth capacity was needed so a second yard was opened in 1859 at Howdon on the opposite bank of the River Tyne. This district became part of Willington Quay after a change of boundaries in the late 1800s and we have standardised, using the name of Willington Quay throughout the ship descriptions.

Above: An artist's impression of the Jarrow Industrial complex courtesy of Kevin Blair. CLICK to enlarge/BACK to return

Plan of the Palmers' Jarrow works in 1887. Click HERE to enlarge. Use Browser BACK button to return. Palmers Shipbuilding and Iron Company Limited was formed in 1865 and the works were then expanded to include an iron rolling mill and blast furnaces. This was one of the earliest examples of Vertical Integration in industry.The company had the highest output of ships for any yard in Britain in 1877, 1879, 1880, 1881, 1882, 1883, 1888 and 1889. However, in 1893 Charles, who had been a great philanthropist for the town of Jarrow, resigned from the company, following heavy losses of £33,000 in 1890/91. In 1906 the overhead electric trolley cranes, with their elliptically shaped gantries, were built at Jarrow and these became a notable feature of the yard.

The iconic gantry cranes at the launch of HMS HERCULES in 1910 The company became a major builder of warships for the Royal Navy, starting with the TERROR in 1856 and building a further 20 major warships plus many small torpedo boat destroyers through to the start of the First World War.In 1910 Sir Charles Palmer's interest in the business was acquired by Lord Furness who, as Chairman, expanded the business. In 1911 the seven-berth shipyard of Robert Stephenson at Hebburn was leased and then purchased in 1912, together with it's 715 foot dry dock. The yard at Willington Quay was then sold to JT Eltringham Ltd who had outgrown their yard at South Shields. During World War One the yard built a battleship, a cruiser, three monitors, eighteen destroyers and two submarines for the Royal Navy, plus four cargo-liners, five standard WAR 'Z' tankers and five 'B' type dry-cargo ships. On the 15th June 1915, the Germans mounted a Zeppelin raid on Tyneside with the shipyards being a specific target. The fitting and coppersmiths workshops were hit and 12 workers were killed. The Company had purchased the small yard of the Amble Shipbuilding Co Ltd at Amble in Northumberland during the War and a 560 feet dry-dock was operated in Swansea from 1922. After the War the Company started to manufacture cargo liners, however tankers soon predominated with over fifty being built between 1921 and 1930. On 24th July 1930 the tanker PETER HURLL became the thousandth ship launched by Palmers, however the last merchant ship built at the yard was the tanker BRITISH STRENGTH completed on 28th April 1931. The last launch took place on 19th July 1932 with the destroyer DUCHESS for the Royal Navy. The complete closure of the shipyard, engine works, blast furnaces and rolling mills in 1933 had a devastating impact on Jarrow as the company had been the town's main employer. Thanks to the efforts of Sir John Jarvis, High Sheriff of Surrey, the yard was partially re-opened. The building that comprised the engine shop was opened as a steel foundry with the steel coming from a shipbreaking facility. The shipbreaking facility broke up some notable ships including the OLYMPIC and BERENGARIA, but the whole enterprise never employed anywhere near the same numbers of workers. In the event this new company was short lived and the whole shipyard site, which had been acquired by National Shipbuilders Security Ltd in 1933, was finally demolished in 1935. Jarrow was heavily dependent on Palmers, and the resultant unemployment (around 70% of the local workforce were unemployed by early 1933) led directly to the Jarrow March of 1936. The terms of sale of the yard prohibited further shipbuilding on the Jarrow site for 40 years. However the Hebburn yard was purchased by Vickers Armstrong and operated as a repair yard under the name Palmers Hebburn Ltd until 1973, when it was acquired by Swan Hunter. |